What actually matters when choosing an electrode

-

Environment — alkaline vs. acidic vs. chloride/saline. Nickel thrives in alkaline; SS 316 is versatile but can suffer in strong acids/chlorides at high temps.

-

Current density & duty cycle — higher current means more heat and gas evolution; pick thicker plates/rigid fixtures.

-

Surface area — mesh lowers overpotential and improves gas release but can be mechanically delicate.

-

Catalysis & overpotential — materials differ for HER/OER kinetics; real‑world mounting and cleaning can dominate.

-

Mechanical & integration — can you clamp/bolt it, weld tabs, or slot it into jigs without bending?

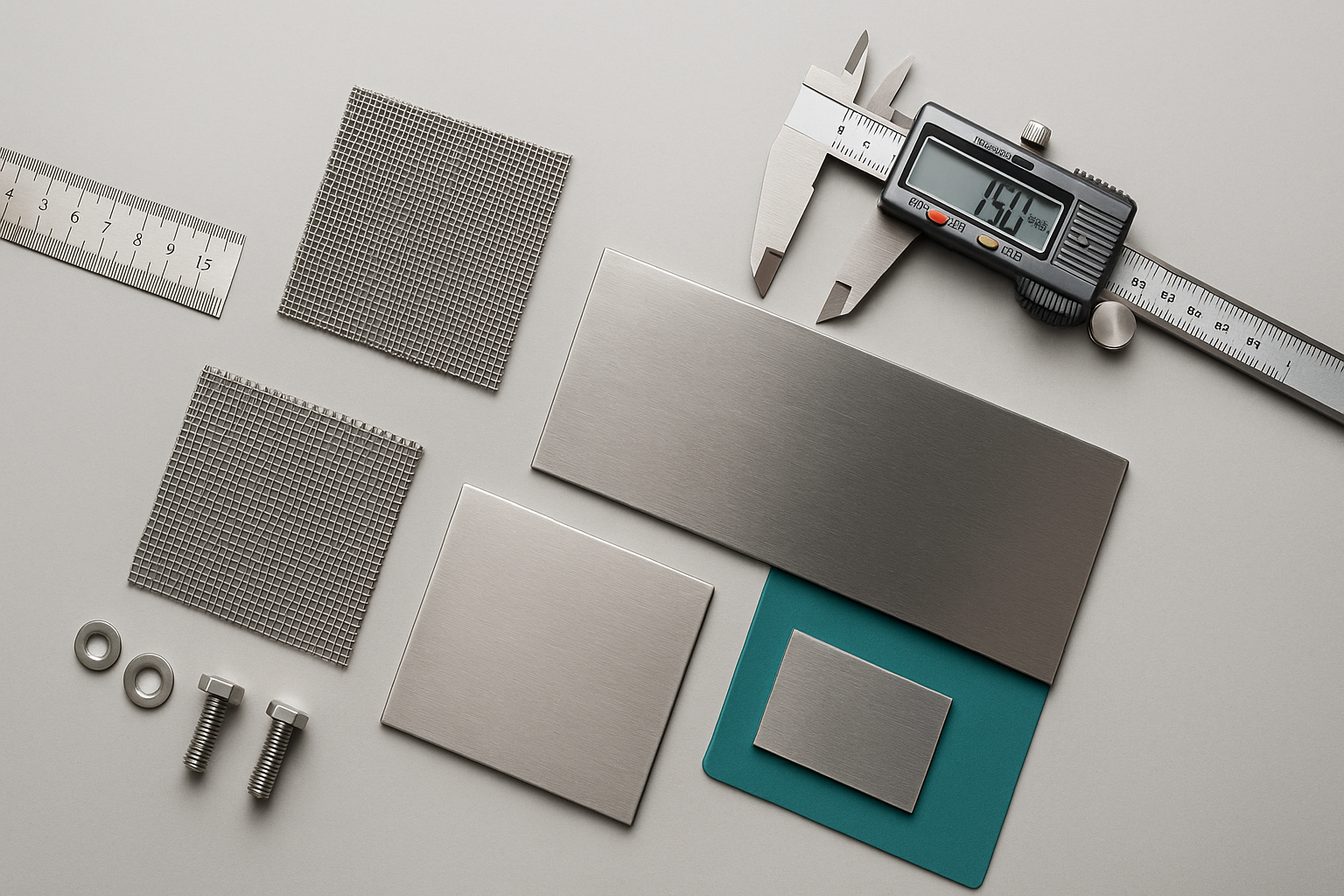

Materials and Forms: Deep Dive

1) Nickel Plate Electrodes (Ni ≥ 99%)

Best for: Alkaline electrolysis (HER/OER), long‑term durability, corrosion/cycle testing in caustic media.

Why choose Ni plate

-

Stable in alkaline environments; widely used in alkaline electrolyzers.

-

Low resistivity with good mechanical strength.

-

Predictable geometry → repeatable current distribution.

Specs at a glance

-

Purity: Ni ≥ 99%

-

Thickness: ~0.5 mm (common stock)

-

Standard sizes: 100×10 to 100×100 mm, multiple variants

-

CAS: 7440‑02‑0

Common setups

-

Cathodes in KOH electrolyzers

-

Electrodeposition mandrels and counter electrodes

-

Corrosion rigs and sensor backplates

2) SS 316 Plate Electrodes

Best for: Cost‑effective prototyping, general electrochemistry in mixed or uncertain environments, saline water systems.

Why choose SS 316

-

Good corrosion resistance due to Cr‑Ni‑Mo composition.

-

Easy to machine, drill, and fixture; widely available.

-

Great value for teaching labs and DIY rigs.

Thickness & rigidity

-

0.8 mm: light and inexpensive; ok for small jigs

-

1.2 mm: balanced rigidity; good default

-

1.5 mm: stiff for high currents/large spans

Standard sizes (all thicknesses)

-

100×10, 100×20, 100×40, 100×60, 100×80, 100×100 mm

-

CAS: 65997‑19‑5

3) Nickel Mesh Electrodes (Mesh 110)

Best for: When you need higher surface area and better bubble detachment to reduce gas‑blocking and lower effective overpotential.

Why choose Ni mesh

-

Drastically increases active area per footprint.

-

Helps bubbles escape during HER/OER → more stable currents.

Specs at a glance

-

Mesh: 110

-

Thickness: 0.15 mm

-

Sizes: 50×50, 80×80, 100×100 mm

-

CAS: 7440‑02‑0

Plates vs Mesh — How to decide

Parameter Plate (Ni / SS 316) Mesh (Ni)

Surface area Lower Higher

Bubble shedding Moderate Excellent

Rigidity High (good for bolting) Lower; add frames

Ohmic drops Lower Can be higher; use shorter leads

Cost per active area Higher Often lower

Tip: For gas‑evolving reactions, start with Nickel Mesh for the working electrode and a rigid plate (Ni or SS 316) as the counter.

Picking size & thickness

-

Electrode area should comfortably exceed the zone of interest in your cell to minimize edge effects.

-

Lead tabs: Keep current paths short; bolt or clamp with conductive washers.

-

Thickness: go 1.2–1.5 mm for large fixtures/high currents; 0.8 mm is fine for compact cells.

Prep, cleaning & maintenance (quick routine)

-

Degrease: Rinse with lab detergent → water → isopropanol; air dry.

-

Light surface refresh: Brief scuff with fine abrasive pad or Scotch‑Brite; rinse thoroughly.

-

Activation rinse (if needed): Short dip in dilute acid or alkaline cleaner compatible with your process; neutralize and rinse. Avoid mixing acids with bleach/chlorinated cleaners.

-

Store dry: Use clean pouches; label material, thickness, last service date.

For long experiments, log current density, electrolyte, pH, and run‑time alongside photos. You’ll spot failure modes early.

Example builds (starter configs)

-

Alkaline electrolyzer (HER focus): Working: Nickel Mesh; Counter: Nickel Plate; Reference: Ag/AgCl or Hg/HgO (per protocol). 20–60 mA·cm⁻² to start.

-

Sensor dev rig: Working: SS 316 Plate; Counter: SS 316 Plate; swap to Ni when moving to alkaline.

-

Corrosion cell (saline): Working: SS 316 Plate; Counter: Nickel Plate; separate reference.

Frequently asked

Q. Can I run SS 316 in strong alkaline for weeks?

Yes, many do for prototypes. For better longevity and lower maintenance, Nickel is preferred.

Q. When should I choose 1.5 mm SS over 1.2 mm?

When current is high, plate span is large, or you need extra stiffness for repeatable jigs.

Q. Why does current drop over time on plates?

Often bubble coverage or fouling. Try nickel mesh, increase flow/agitation, or occasionally re‑condition the surface.

Ready to build? Shop electrodes

-

Nickel Plate Electrodes → https://dbaedge.com/product/2

-

Nickel Mesh Electrodes → https://dbaedge.com/product/4

-

SS 316 Plate Electrodes →

-

0.8 mm → https://dbaedge.com/product/5

-

1.2 mm → https://dbaedge.com/product/6

-

1.5 mm → https://dbaedge.com/product/7

-

Need help sizing or customizing? Email support@dbaedge.com with your application, electrolyte, and target current density.